Cracks in Cymbals – Why They Happen and How to Prevent Them

Written by Gunnar Egede Kristiansen - 6 March 2025

You may have experienced it yourself, or know someone who has: a cymbal cracks, splits, dies – call it what you want, though it’s safe to say this isn’t a particularly welcome “child.”

But why does it actually happen? There can be several reasons. These reasons don’t have to stand alone – in fact, a combination of factors often leads to the unfortunate result.

Here are some possible causes of cymbal cracks:

- Incorrect cymbal mounting

- Poor playing technique

- Manufacturing weaknesses

- Neglect or improper handling

Let’s take a closer look at each.

Incorrect cymbal mounting

When you strike your crash cymbal – and I’m using a crash as an example here, as they are most often the ones to crack – all the energy from your drumstick ripples throughout the cymbal. It’s no quiet affair, and it looks quite spectacular when filmed in slow motion – see for yourself:

Since all this energy shakes the cymbal vigorously, it’s important that the cymbal is mounted in a way that allows it to move as freely as possible. So tightening it down hard with extra felt and a tight wingnut is a definite no-go. Instead, think about how to relieve the cymbal and make its life as easy as possible.

You might compare a very heavy stand with minimal give to a lighter one that can absorb some of the shock. The lighter stand actually helps take some of the strain off the cymbal. To give a perhaps extreme analogy: if someone were to punch you, would you prefer your head be clamped in place or free to turn with the impact?

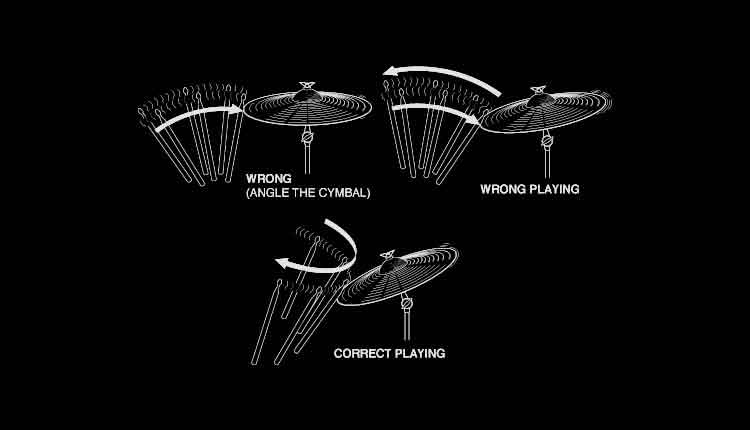

As unpleasant as that sounds, it illustrates how important it is to give the cymbal ideal working conditions. Angle matters too – hanging your cymbal completely flat and striking its edge does nothing good for its lifespan. Cracks from this setup typically start at the edge and move inward. If you tilt the cymbal too much, though, it becomes difficult to play. The trick is finding the sweet spot – good playing feel without unnecessary stress on the cymbal.

Poor playing technique

This brings us to your stick control. One of the biggest factors is, quite simply, the drummer. Different drummers handle their sticks in very different ways. Just like with cymbal mounting, the tighter you grip your sticks, the more harshly your cymbal gets treated. Ideally, your stroke should glide across the cymbal – not dig into it (see illustration below). It’s a technique you have to learn, but it’s not difficult – and once you’ve got it, it becomes second nature. And your cymbal will thank you for it.

Manufacturing weaknesses

Now we come to the explanation most drummers instinctively reach for when disaster strikes: the cymbal itself is to blame. Maybe it was poorly made. Maybe it had a flaw from the beginning.

And sometimes that’s true. Cymbals are hammered by hand, leaving hammer marks. A mark that’s deeper than others can become a weak point. You’ll often see cracks radiating from one such spot.

It can also be the grooves – cracks can follow a groove line. You can always debate whether a crack would have happened if the cymbal had been handled differently. If it hadn’t been played at all, it wouldn’t have cracked. So the truth usually lies somewhere between “no use” and “extreme and prolonged use.” That makes it tricky for retailers and manufacturers when assessing broken cymbals. Ultimately, it’s up to each shop, in dialogue with the importer and cymbal brand, to make that call. Shops want happy customers – but don’t want to be taken advantage of either.

Neglect or improper handling

Now we reach the final category. Cymbals can grow weaker over time. Most people have heard of metal fatigue, but poor treatment – especially during transport – can also do serious damage. That’s why retailers often inspect the cymbal’s condition if you ask for a replacement. If it has a keyhole or dents on the edge, it may not have been properly cared for.

Are thicker cymbals stronger than thin ones?

There’s a common myth that thick cymbals are stronger. In reality, it’s often the opposite. Why? If you watch a slow-motion video of a crashing cymbal vibrating wildly, it becomes clearer. A thicker cymbal has more mass that needs to be moved, so the impact is more violent. A thinner cymbal moves more easily – it’s lighter and more flexible. That’s the theory anyway, and it seems to hold up when we look at which cymbals come back cracked.

What can you do if your cymbal cracks?

If the damage is done and you’re out of warranty, there may still be hope. Depending on the crack’s size and location, it might be possible to salvage the cymbal by cutting around the crack. Especially if the crack starts from the edge and moves inward – a soft curve can sometimes stop it from spreading further.

If the crack is in the middle of the cymbal, drilling a hole at each end of the crack may suffice. Often, it’s also necessary to remove some material along the crack to avoid unpleasant noises.

In any case, it’s best to consult a specialist – unless you have experience working with metal. If you want to try it yourself, here’s a useful guide.

Summary

So what can you do to prevent cymbal damage?

Make sure your cymbal is properly mounted

- Ensure there’s intact plastic or rubber protection on the stand post.

- Check that the felt is intact and sufficient.

- Don’t overtighten the cymbal – let it move freely.

- Consider an isolation mount – like a CRS holder. These cost a bit but improve sound and cymbal life.

- Mount your cymbal at an angle where you don’t strike it directly on the edge.

- Don’t play harder than necessary.

- Show “mechanical empathy” to your cymbal while playing!